Welcome to My Blog!

Before we dive into the content, I’d love for you to join me on my social media platforms where I share more insights, engage with the community, and post updates. Here’s how you can connect with me:

Facebook:https://www.facebook.com/profile.php?id=100085401406977

LinkedIn:https://www.linkedin.com/showcase/102680001/admin/dashboard/

Now, let’s get started on our journey together. I hope you find the content here insightful, engaging, and valuable.

Introduction

When it comes to piping materials, carbon steel pipes stand out due to their durability and versatility. Used in various applications ranging from construction to oil and gas industries, understanding carbon steel pipes is crucial for anyone involved in selection or procurement. This guide aims to provide detailed insights into different types, standards, uses, and considerations when purchasing carbon steel pipes.

Understanding Carbon Steel Pipes

What are Carbon Steel Pipes?

Carbon steel pipes are made from steel with carbon content ranging from 0.05% to 2.0%, which can influence their properties significantly. These pipes are recognized for their strength, making them ideal for high-pressure applications. They are categorized mainly into three types based on the carbon content: low carbon, medium carbon, and high carbon.

Types of Carbon Steel Pipes

Low Carbon Steel Pipes

Low carbon steel pipes, also known as mild steel pipes, contain approximately 0.05% to 0.25% carbon. They are generally more malleable and ductile, making them suitable for welding and bending.

Medium Carbon Steel Pipes

With a carbon content ranging from 0.25% to 0.6%, medium carbon steel pipes combine strength with ductility, offering enhanced properties for applications that require both.

High Carbon Steel Pipes

High carbon steel pipes contain 0.6% to 2.0% carbon, leading to increased hardness and strength. However, their brittleness can limit their versatility in certain applications.

Key Specifications and Standards for Carbon Steel Pipes

Dimensions and Schedules

Carbon steel pipes come in various sizes and wall thicknesses, denoted by the nominal pipe size (NPS) and schedule (SCH). The dimensions adhere to standards set by organizations such as the American National Standards Institute (ANSI) and the American Society for Testing and Materials (ASTM).

| Nominal Pipe Size (NPS) | Schedule 40 | Schedule 80 | Schedule 160 |

|---|---|---|---|

| 1/2 | 0.109 | 0.147 | 0.203 |

| 1 | 0.133 | 0.179 | 0.254 |

| 2 | 0.154 | 0.218 | 0.331 |

| 3 | 0.216 | 0.300 | 0.372 |

| 4 | 0.237 | 0.337 | 0.432 |

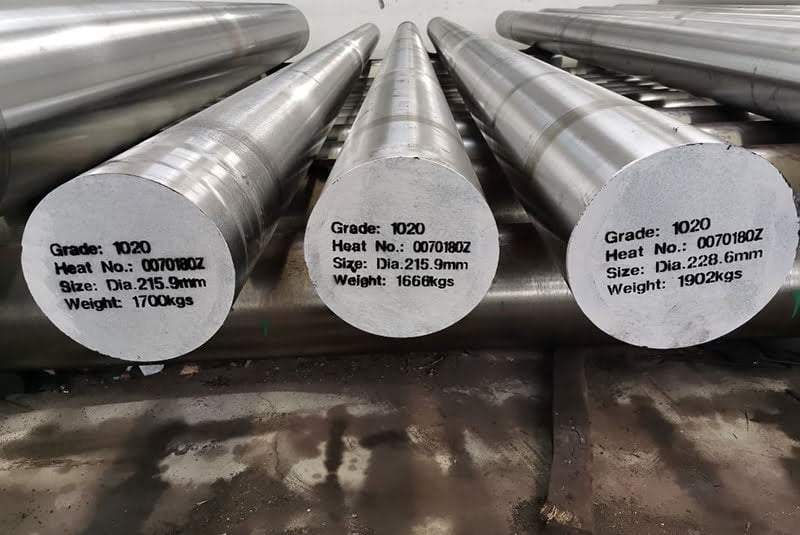

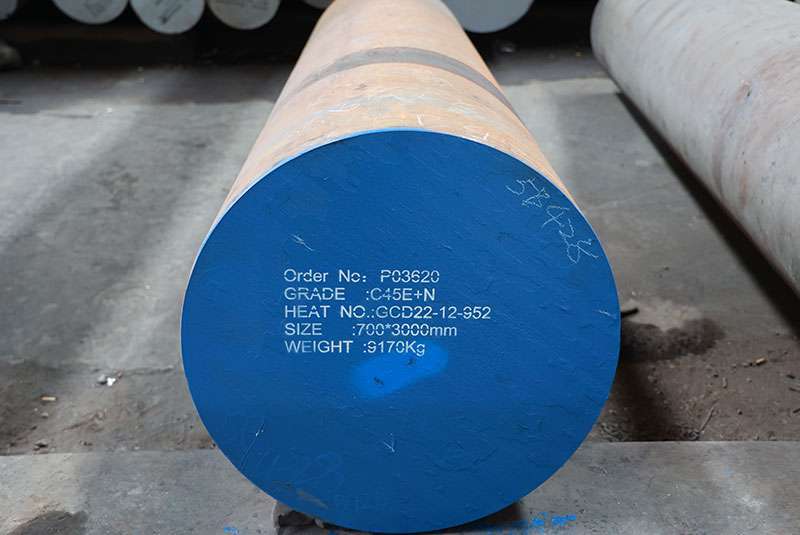

Material Grades of Carbon Steel Pipes

The most common grades of carbon steel pipes are defined by the ASTM standards, such as ASTM A53, ASTM A36, and ASTM A106. Each grade has different mechanical and chemical properties, determining its suitability for specific applications.

Applications of Carbon Steel Pipes

Oil and Gas Industry

Carbon steel pipes are extensively used in the oil and gas sector for transporting oil, gas, and water. Their high strength and ability to withstand high pressures make them a top choice for drilling operations and pipelines.

Construction and Infrastructure

Carbon steel pipes are fundamental in construction projects, including structural supports and framing. Due to their cost-effectiveness and strength, they are widely utilized for water supply and drainage systems.

Purchasing Carbon Steel Pipes: What to Consider

Quality Assurance and Testing

Before purchasing carbon steel pipes, it’s crucial to check for quality certifications and testing methods, such as ultrasonic testing and radiographic examination, which ensure the integrity of the pipes.

Supplier Reputation and Reliability

Selecting a reputable supplier is vital to ensure the quality of the pipes and on-time delivery. Research suppliers and check reviews or feedback from previous clients.

Pricing and Budget

While price shouldn’t be the sole determinant, it’s important to compare prices from different suppliers. Ensure the pricing aligns with your budget while also considering the quality of the pipes offered.

Conclusion

In summary, carbon steel pipes are essential components in various industries, thanks to their strength, versatility, and affordability. When purchasing, it is vital to consider factors such as type, specifications, applications, supplier reputation, and quality assurance processes. By following this comprehensive buying guide, you can make informed decisions that meet your project needs.

FAQs

What are carbon steel tubes, and what are their primary uses?

Carbon steel tubes are commonly used in various industries due to their strength and durability. They are primarily used in construction, plumbing, and industrial applications.

How do carbon steel pipes compare to stainless steel tubes?

Carbon steel tubes are generally more affordable than stainless steel pipes but are less resistant to corrosion. They are ideal for applications where strength is more critical than corrosion resistance.

What are the different grades of carbon steel tubes?

Carbon steel tubes come in various grades, such as A106, A53, and API 5L, each suited for specific applications based on their mechanical properties and chemical composition.

How do I choose the right size of carbon steel tubes for my project?

Choosing the right size of carbon steel tubes depends on factors like the intended application, pressure requirements, and flow rate. It’s essential to consult sizing charts and project specifications.

What is the lifespan of carbon steel tubes in different environments?

The lifespan of carbon steel tubes can vary depending on the environment. In dry and non-corrosive conditions, they can last several decades, while in corrosive environments, they may require coatings or more frequent replacements.

Are carbon steel tubes suitable for high-temperature applications?

Yes, carbon steel tubes are often used in high-temperature applications due to their ability to withstand heat without losing strength. However, the specific grade of steel should be chosen based on the temperature range.

What are the common coating options for carbon steel tubes?

To enhance the corrosion resistance of carbon steel tubes, common coatings include galvanizing, epoxy, and polyethylene. The choice of coating depends on the environmental conditions and intended use.

Can carbon steel tubes be welded easily?

Yes, carbon steel tubes are known for their excellent weldability, making them suitable for various fabrication and construction projects.

How do I maintain carbon steel tubes to extend their lifespan?

Regular maintenance of carbon steel tubes includes inspecting for corrosion, applying protective coatings, and ensuring that they are not exposed to environments that could accelerate wear.

Where can I buy high-quality carbon steel tubes?

High-quality carbon steel tubes can be purchased from specialized industrial suppliers, manufacturers, and online platforms that offer a range of sizes and grades to suit different project needs.