Introduction

Carbon steel pipes are integral components in various industries, serving crucial roles in infrastructure, construction, oil and gas, and many other sectors. Understanding the journey of carbon steel pipes from manufacturing to distribution is essential for appreciating their importance and ensuring their quality and reliability. In this blog post, we will explore the different stages of this journey, highlighting key processes and considerations along the way.

Manufacturing Process

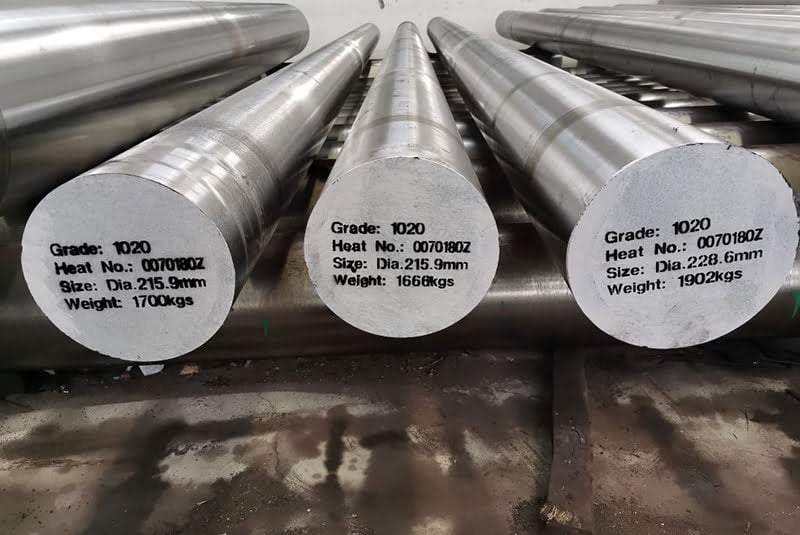

Steelmaking: The molten iron is further refined in a steelmaking process, such as the basic oxygen process (BOP) or electric arc furnace (EAF), to remove impurities and adjust the carbon content. The resulting steel is then cast into slabs or billets, which serve as the starting material for pipe manufacturing.

Hot Rolling: Slabs or billets are heated to a high temperature and passed through a series of rolling mills, reducing their thickness and increasing their length. This process, known as hot rolling, shapes the steel into long, flat strips called skelp.

Pipe Forming: The skelp is then fed into a forming mill, where it is progressively curved and welded into a cylindrical shape. This process, known as pipe forming, creates the basic structure of the carbon steel pipe.

Sizing and Finishing: The formed pipe undergoes sizing and finishing processes to ensure the desired dimensions, surface finish, and wall thickness. This may involve processes like welding, trimming, straightening, and heat treatment.

Quality Control: Throughout the manufacturing process, rigorous quality control measures are implemented to ensure the pipes meet the specified standards for strength, dimensional accuracy, and surface quality.

Distribution Channels

Pipe Mills: Carbon steel pipes are typically produced by large pipe mills that specialize in the manufacturing process. These mills supply pipes to various distributors and wholesalers.

Distributors and Wholesalers: Distributors and wholesalers act as intermediaries between pipe mills and end users. They maintain large inventories of pipes in various sizes, grades, and lengths, catering to the diverse needs of their customers.

Retailers and Contractors: Retailers and contractors purchase pipes from distributors and wholesalers to supply construction projects, industrial facilities, and other end users.

Direct Sales: Some pipe mills may sell directly to large-scale projects or end users, bypassing the distribution chain.In doing so, these mills can potentially offer lower prices and faster delivery times to their customers. By cutting out the middleman, they can streamline the purchasing process and provide a more direct line of communication between the manufacturer and the buyer. This can be especially beneficial for projects that require large quantities of pipe or have specific customization needs. Overall, bypassing the distribution chain can result in cost savings and increased efficiency for both the pipe mill and the end user.

Applications of Carbon Steel Pipes

Oil and Gas Transportation: Carbon steel pipes are extensively used for transporting oil and gas from production sites to refineries, storage facilities, and distribution networks. Their strength and durability make them suitable for high-pressure applications.

Water Supply and Distribution: Carbon steel pipes form the backbone of municipal water supply and distribution systems, carrying water from treatment plants to homes and businesses. Their corrosion resistance and ability to withstand pressure fluctuations make them ideal for this application.

Construction and Infrastructure: Carbon steel pipes are widely used in construction projects, serving as structural elements in buildings, bridges, and other infrastructure. Their strength, versatility, and cost-effectiveness make them a popular choice for contractors.

Industrial Applications: Carbon steel pipes find diverse applications in various industries, including power generation, chemical processing, and manufacturing. Their ability to handle high temperatures, pressures, and corrosive environments makes them suitable for a wide range of industrial processes.

Tables and Data Analysis

Here’s a comparative analysis of different carbon steel pipe manufacturing methods:

| Method | Advantages | Disadvantages |

|---|---|---|

| UOE | High precision, good for large diameters | More expensive, less flexible for small runs |

| ERW | Cost-effective, fast production | Not suitable for very thick walls |

| SAW | Suitable for thick walls | Less precision compared to UOE |

This table illustrates the different strengths and weaknesses of each manufacturing method, showing how they cater to specific needs.

Conclusion

The journey of carbon steel pipes from manufacturing to distribution is a complex and intricate process that ensures these vital components reach their end-users in the best possible condition. As the demand for carbon steel pipes continues to grow, so does the need for efficient manufacturing and distribution practices. The versatility and reliability of carbon steel pipes make them indispensable in our modern world, and their importance is set to endure for many years to come.

FAQ

What is the primary material used in carbon steel pipes?

- The primary material used in carbon steel pipes is iron, with carbon being the main alloying element.

How are carbon steel pipes shaped?

- Carbon steel pipes are shaped through various methods, including UOE, ERW, and SAW, each suitable for different pipe diameters and wall thicknesses.

What are carbon steel pipes used for?

- Carbon steel pipes are used in the oil and gas industry, construction, automotive applications, and mechanical engineering.

How are carbon steel pipes distributed?

- Carbon steel pipes are distributed through a network of logistics and transportation services, from the manufacturing plant to distribution centers and finally to the customers.

What are the key factors to consider when choosing carbon steel pipes?

- Key factors include the pipe’s intended application, required pressure and temperature ratings, material grade, and the compatibility of the manufacturing method with the project’s specific needs.