Introduction

The 4140 steel alloy is a popular material in various engineering and industrial applications due to its impressive mechanical properties. One of the key attributes that make 4140 steel highly desirable is its yield strength. In this article, we will explore how the 4140 yield strength impacts mechanical performance, providing a comprehensive understanding of its applications and benefits. We will also answer frequently asked questions (FAQs) to address common inquiries about this remarkable material.

Understanding 4140 Yield Strength

What is Yield Strength?

Yield strength is a material property that defines the stress at which a material begins to deform plastically. Before reaching the yield point, the material will deform elastically and return to its original shape when the applied stress is removed. However, once the yield strength is surpassed, permanent deformation occurs.

Yield Strength of 4140 Steel

The yield strength of 4140 steel is approximately 655 MPa (95,000 psi). This high yield strength makes it suitable for demanding applications where mechanical performance and durability are critical. The exact yield strength can vary depending on the specific composition and heat treatment processes applied to the steel.

Applications of 4140 Steel Based on Yield Strength

Automotive Industry

In the automotive industry, components such as crankshafts, gears, and axles require materials that can withstand high stress and provide reliable performance. The 4140 yield strength ensures these parts maintain their structural integrity under heavy loads and high-speed conditions.

Construction and Structural Engineering

4140 steel is widely used in construction and structural engineering for components like bolts, couplings, and other high-strength fittings. The high yield strength of 4140 steel ensures these parts can support significant loads without deforming, contributing to the overall safety and stability of structures.

Oil and Gas Industry

In the oil and gas industry, equipment such as drill collars, drive shafts, and pipeline components are often exposed to harsh environments and extreme pressures. The superior yield strength of 4140 steel allows these components to endure such conditions, reducing the risk of failure and enhancing operational reliability.

Impact of 4140 Yield Strength on Mechanical Performance

Enhanced Load-Bearing Capacity

The high yield strength of 4140 steel significantly enhances its load-bearing capacity. This attribute is crucial for applications involving heavy machinery and equipment, where the material must support substantial weight without yielding.

Resistance to Deformation

Materials with high yield strength, such as 4140 steel, exhibit excellent resistance to deformation. This characteristic is particularly important in applications where precision and dimensional stability are essential, ensuring components maintain their shape and functionality under stress.

Durability and Longevity

The durability of 4140 steel, attributed to its high yield strength, translates to longer service life for components made from this material. This longevity reduces the need for frequent replacements, resulting in cost savings and improved efficiency for industries utilizing 4140 steel.

Table: Comparison of Yield Strength in Different Steel Grades

| Steel Grade | Yield Strength (MPa) | Common Applications |

|---|---|---|

| 4140 | 655 | Automotive parts, structural components, oil and gas |

| 1018 | 370 | General purpose, low-stress applications |

| 4340 | 710 | High-strength aerospace, military applications |

| A36 | 250 | Construction, structural beams and columns |

| D2 Tool Steel | 550 | Tool and die making, cutting tools |

Factors Influencing 4140 Yield Strength

Heat Treatment

Heat treatment processes such as quenching and tempering can significantly influence the yield strength of 4140 steel. These treatments modify the microstructure of the steel, enhancing its mechanical properties and making it suitable for specific applications.

Alloy Composition

The composition of 4140 steel, including elements like chromium, molybdenum, and manganese, contributes to its high yield strength. These alloying elements enhance the hardness and toughness of the steel, improving its performance under stress.

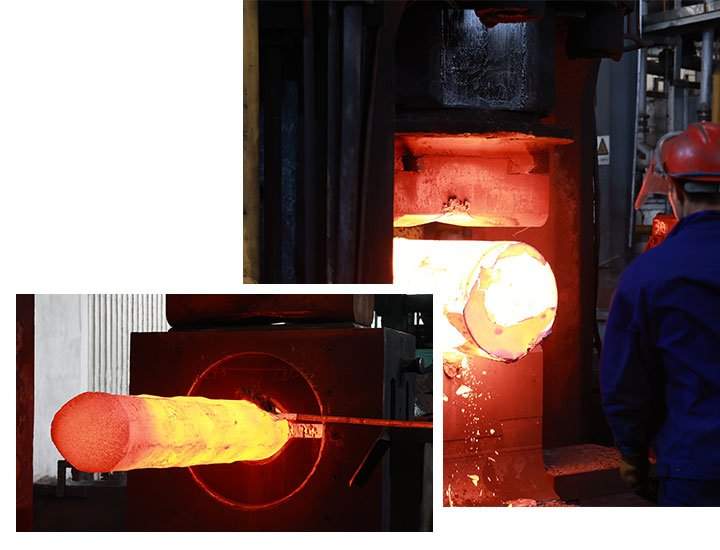

Manufacturing Processes

Manufacturing processes, including forging, machining, and forming, can also impact the yield strength of 4140 steel. Proper handling and processing are essential to maintain the desired mechanical properties and ensure the material performs as expected.

Conclusion

The 4140 yield strength is a defining characteristic that significantly impacts the mechanical performance of this steel alloy. Its high yield strength makes it an ideal choice for various demanding applications across multiple industries. Understanding the benefits and applications of 4140 steel based on its yield strength allows engineers and manufacturers to make informed decisions when selecting materials for their projects. By leveraging the exceptional properties of 4140 steel, industries can achieve greater efficiency, reliability, and longevity in their operations.

FAQ

What is the 4140 yield strength?

The 4140 yield strength refers to the stress level at which 4140 steel begins to deform plastically. This is typically around 655 MPa (95,000 psi), making it a highly durable and reliable material for various applications.

How does heat treatment affect the 4140 yield strength?

Heat treatment processes, such as quenching and tempering, can significantly enhance the 4140 yield strength. These treatments alter the microstructure of the steel, improving its mechanical properties and making it more suitable for high-stress applications.

What applications benefit from the high 4140 yield strength?

Applications that benefit from the high 4140 yield strength include automotive parts like gears and axles, construction components such as bolts and couplings, and oil and gas industry equipment like drill collars and drive shafts. The high yield strength ensures durability and resistance to deformation.

How does the 4140 yield strength compare to other steel grades?

The 4140 yield strength, typically around 655 MPa, is higher than that of many other steel grades like 1018 (370 MPa) and A36 (250 MPa), but slightly lower than 4340 steel (710 MPa). This makes 4140 steel suitable for demanding applications requiring moderate to high strength.

Why is the 4140 yield strength important for structural engineering?

The 4140 yield strength is crucial for structural engineering because it ensures components can withstand significant loads without permanent deformation. This property is essential for maintaining the integrity and safety of structures under stress.

Can 4140 steel be used in high-temperature environments given its yield strength?

Yes, 4140 steel can be used in high-temperature environments, although its yield strength may be affected by prolonged exposure to high temperatures. It is important to consider these factors when selecting 4140 steel for such applications.

What is the impact of alloy composition on 4140 yield strength?

The alloy composition, including elements like chromium, molybdenum, and manganese, contributes to the high 4140 yield strength. These elements enhance the hardness, toughness, and overall mechanical performance of the steel.

How does the 4140 yield strength affect machining processes?

The high 4140 yield strength makes the steel more resistant to deformation during machining processes. This property is beneficial for creating precise and durable components, but it also means that more robust tools and techniques may be required for machining.

What role does 4140 yield strength play in the oil and gas industry?

In the oil and gas industry, the 4140 yield strength ensures that components such as pipeline fittings, drill collars, and drive shafts can endure extreme pressures and harsh environments. This reliability is critical for safe and efficient operations.

How is the 4140 yield strength measured?

The 4140 yield strength is measured using a tensile test, where a sample of the steel is subjected to increasing stress until it deforms plastically. The stress level at which this deformation occurs is recorded as the yield strength.