Welcome to My Blog!

Before we dive into the content, I’d love for you to join me on my social media platforms where I share more insights, engage with the community, and post updates. Here’s how you can connect with me:

Facebook:https://www.facebook.com/profile.php?id=100085401406977

LinkedIn:https://www.linkedin.com/showcase/102680001/admin/dashboard/

Now, let’s get started on our journey together. I hope you find the content here insightful, engaging, and valuable.

Table of Contents

Introduction

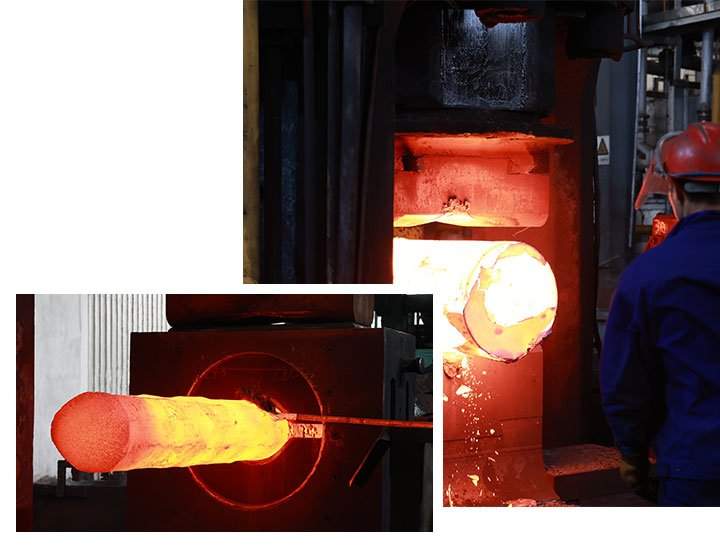

The steel tensile test is a fundamental procedure used in materials science and engineering to evaluate the mechanical properties of steel. By measuring how a sample of steel responds to tensile forces, engineers can determine essential characteristics such as strength, ductility, and elasticity. Understanding the results of a steel tensile test is crucial for industries that rely on steel components, including construction, automotive, and manufacturing. However, various factors can significantly influence the results of these tests. In this article, we will explore the key factors that affect steel tensile test outcomes and their implications for engineering applications.

What is a Steel Tensile Test?

A steel tensile test involves applying a uniaxial tensile load to a steel sample until it deforms and ultimately breaks. The test measures several mechanical properties, including:

- Yield Strength: The stress at which the material begins to deform plastically.

- Ultimate Tensile Strength (UTS): The maximum stress the material can withstand.

- Elongation: The percentage increase in length that occurs before fracture.

- Reduction of Area: The decrease in cross-sectional area at the point of fracture.

The test typically follows standards established by organizations such as ASTM (American Society for Testing and Materials) or ISO (International Organization for Standardization).

Key Factors Influencing Steel Tensile Test Results

Several factors can influence the outcomes of a steel tensile test. Understanding these factors is essential for accurately interpreting test results and making informed engineering decisions.

Material Composition

The chemical composition of steel significantly affects its mechanical properties. Different alloying elements can enhance or diminish specific traits:

- Carbon Content: Higher carbon content generally increases strength and hardness but reduces ductility.

- Alloying Elements: Elements such as manganese, chromium, and nickel can improve strength, toughness, and corrosion resistance.

The table below summarizes the influence of key alloying elements on steel properties:

| Element | Effect on Steel |

|---|---|

| Carbon | Increases strength; reduces ductility |

| Manganese | Improves hardenability and toughness |

| Chromium | Enhances corrosion resistance |

| Nickel | Increases toughness and impact resistance |

| Molybdenum | Improves strength at high temperatures |

Heat Treatment

Heat treatment processes can significantly alter the microstructure of steel, thereby affecting its mechanical properties:

- Annealing: Softens steel, increasing ductility and reducing hardness.

- Quenching: Increases strength and hardness but may introduce brittleness.

- Tempering: Reduces brittleness while maintaining a good balance of strength and ductility.

The choice of heat treatment should align with the desired properties for the intended application.

Testing Conditions

The conditions under which a steel tensile test is performed can also impact the results. Key factors include:

- Temperature: Elevated temperatures can enhance ductility but may reduce strength.

- Loading Rate: The speed at which the load is applied can influence the material’s response. A faster loading rate may result in higher strength readings due to strain rate sensitivity.

Ensuring consistent testing conditions is crucial for reliable and comparable results.

Sample Preparation

How the steel sample is prepared before testing can significantly influence the results. Key considerations include:

- Geometry: The shape and dimensions of the test specimen must conform to established standards (e.g., ASTM E8).

- Surface Finish: Surface defects or irregularities can act as stress concentrators, leading to premature failure.

- Grain Structure: The orientation of the grain structure can impact the strength and ductility of the steel.

Proper sample preparation is essential for accurate testing.

Equipment Calibration and Maintenance

The accuracy of a steel tensile test relies heavily on the equipment used. Factors to consider include:

- Calibration: Regular calibration of testing machines ensures accurate force and elongation measurements.

- Maintenance: Routine maintenance of equipment minimizes the risk of errors during testing.

Well-maintained and calibrated equipment is critical for obtaining reliable results.

Implications of Steel Tensile Test Results

The outcomes of a steel tensile test have significant implications for engineering and design. Understanding how the key factors influence these results is crucial for making informed decisions.

Design and Material Selection

Test results guide engineers in selecting appropriate materials for specific applications. For instance, a project requiring high strength and low weight may favor high-carbon steel, while applications that demand good impact resistance may benefit from alloyed steels with higher ductility.

Quality Control

Regular tensile testing is an essential aspect of quality control in manufacturing processes. By assessing the mechanical properties of steel batches, manufacturers can ensure compliance with specifications and standards.

Failure Analysis

When structural failures occur, tensile test results can aid in identifying the root causes. Understanding how material properties influence performance can help prevent future issues and improve design practices.

Conclusion

The steel tensile test is a critical evaluation tool that provides valuable insights into the mechanical properties of steel. Understanding the various factors that influence test results—such as material composition, heat treatment, testing conditions, sample preparation, and equipment calibration—enables engineers to make informed decisions about material selection and design. By considering these factors, industries can enhance the safety, reliability, and performance of their steel structures.

FAQ

What is the significance of yield strength in a steel tensile test?

Yield strength is significant because it indicates the maximum stress that a material can withstand without permanent deformation. It is crucial for ensuring that structural components can support loads without failing.

How does temperature affect the results of a steel tensile test?

Temperature can greatly influence the mechanical properties of steel. Higher temperatures generally increase ductility but may decrease strength, making it essential to conduct tests at the expected service temperatures.

Why is sample preparation important for tensile testing?

Proper sample preparation is essential to minimize variability in test results. Factors like geometry, surface finish, and grain structure can significantly affect the outcome of the test.

How often should tensile testing equipment be calibrated?

Tensile testing equipment should be calibrated regularly, ideally before each testing session or at predetermined intervals, to ensure accurate measurements.

Can tensile test results be used to predict the performance of steel in real-world applications?

Yes, tensile test results provide a reliable basis for predicting how steel will perform under various loads and conditions, making them essential for engineering design and safety assessments.