Introduction

D2 steel is a high-carbon, high-chromium tool steel known for its excellent wear resistance and durability. It is commonly used in the manufacturing of cutting tools, dies, and industrial knives. Proper heat treatment is essential to maximize the performance and longevity of D2 steel. In this article, we will explore the top methods for D2 steel heat treatment, focusing on key processes, parameters, and outcomes. We will also address some frequently asked questions (FAQ) to provide a comprehensive understanding of this critical procedure.

Understanding D2 Steel Composition

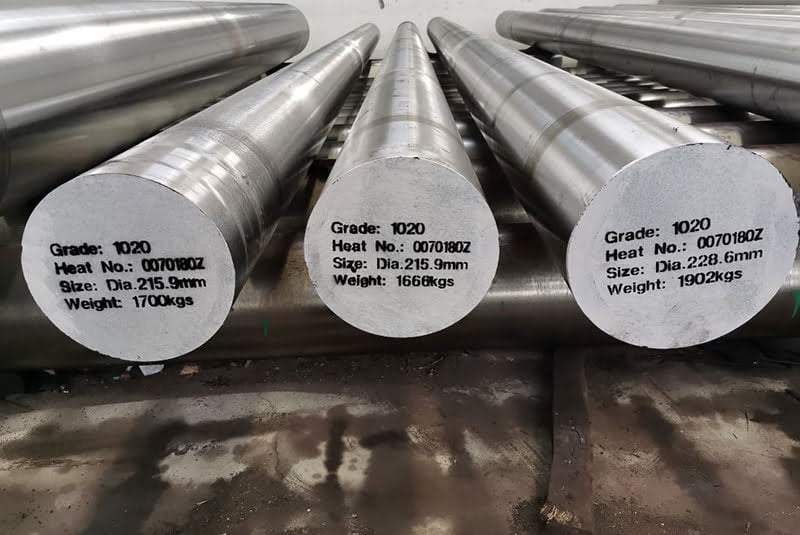

Before diving into the heat treatment methods, it is crucial to understand the composition of D2 steel. This tool steel typically contains the following elements:

| Element | Percentage (%) |

|---|---|

| Carbon (C) | 1.50 – 1.60 |

| Chromium (Cr) | 11.00 – 13.00 |

| Molybdenum (Mo) | 0.70 – 1.20 |

| Vanadium (V) | 0.20 – 0.50 |

| Manganese (Mn) | 0.60 – 0.90 |

| Silicon (Si) | 0.10 – 0.40 |

The high chromium content provides excellent corrosion resistance and hardness, while the carbon contributes to the steel’s toughness and wear resistance. Understanding these properties is crucial for effective D2 steel heat treatment.

Heat Treatment Methods

Annealing

Annealing is a crucial heat treatment process for D2 steel. It involves heating the steel to a specific temperature and then slowly cooling it. This process helps to soften the steel, making it easier to machine and shape.

Process:

- Heat the D2 steel to a temperature range of 1650°F to 1700°F (899°C to 927°C).

- Hold the temperature for a prolonged period to ensure uniform heating.

- Allow the steel to cool slowly in the furnace to room temperature.

| Annealing Parameters | Values |

|---|---|

| Temperature (°F) | 1650 – 1700 |

| Holding Time (hours) | 2 – 4 |

| Cooling Method | Furnace cooling |

Hardening

Hardening increases the hardness and strength of D2 steel, making it suitable for high-wear applications. This method involves heating the steel to a higher temperature and then rapidly cooling it.

Process:

- Heat the D2 steel to a temperature range of 1800°F to 1875°F (982°C to 1024°C).

- Soak the steel at this temperature to ensure complete transformation.

- Quench the steel in oil or air to rapidly cool it.

| Hardening Parameters | Values |

|---|---|

| Temperature (°F) | 1800 – 1875 |

| Soaking Time (minutes) | 30 – 45 |

| Quenching Medium | Oil/Air |

Tempering

Tempering follows the hardening process and aims to reduce brittleness while retaining hardness. It involves reheating the hardened steel to a lower temperature and then cooling it.

Process:

- Heat the hardened D2 steel to a temperature range of 300°F to 500°F (149°C to 260°C).

- Maintain the temperature for a specific period.

- Allow the steel to cool in air.

| Tempering Parameters | Values |

|---|---|

| Temperature (°F) | 300 – 500 |

| Holding Time (hours) | 1 – 2 |

| Cooling Method | Air cooling |

Cryogenic Treatment

Cryogenic treatment involves cooling the D2 steel to sub-zero temperatures to enhance its wear resistance and dimensional stability.

Process:

- Cool the D2 steel to a temperature range of -100°F to -300°F (-73°C to -184°C).

- Hold the temperature for several hours.

- Gradually return the steel to room temperature.

| Cryogenic Treatment Parameters | Values |

|---|---|

| Temperature (°F) | -100 to -300 |

| Holding Time (hours) | 8 – 24 |

| Warming Method | Gradual return to room temperature |

Stress Relieving

Stress relieving is performed to reduce residual stresses induced during machining or other processes.

Process:

- Heat the D2 steel to a temperature range of 1100°F to 1300°F (593°C to 704°C).

- Hold the temperature for a specific period.

- Allow the steel to cool in the furnace.

| Stress Relieving Parameters | Values |

|---|---|

| Temperature (°F) | 1100 – 1300 |

| Holding Time (hours) | 1 – 2 |

| Cooling Method | Furnace cooling |

Benefits of Proper Heat Treatment

Proper heat treatment of D2 steel offers several benefits, including:

- Enhanced hardness and wear resistance.

- Improved dimensional stability.

- Increased toughness and impact resistance.

- Reduced internal stresses.

- Extended tool life and performance.

Conclusion

D2 steel heat treatment is a vital process to achieve the desired mechanical properties and performance. By understanding and applying the appropriate heat treatment methods—annealing, hardening, tempering, cryogenic treatment, and stress relieving—you can optimize the characteristics of D2 steel for various industrial applications. Properly treated D2 steel exhibits exceptional hardness, wear resistance, and toughness, making it a preferred choice for many tool and die applications.

FAQ

Q1: What is the ideal temperature range for hardening D2 steel?

The ideal temperature range for hardening D2 steel is between 1800°F and 1875°F (982°C to 1024°C).

Q2: How long should D2 steel be soaked during the hardening process?

D2 steel should be soaked for 30 to 45 minutes during the hardening process to ensure complete transformation.

Q3: Can D2 steel be air-cooled during quenching?

Yes, D2 steel can be air-cooled during quenching, although oil quenching is also a common method.

Q4: What is the purpose of cryogenic treatment for D2 steel?

Cryogenic treatment enhances the wear resistance and dimensional stability of D2 steel by cooling it to sub-zero temperatures.

Q5: Why is tempering necessary after hardening D2 steel?

Tempering is necessary to reduce the brittleness of D2 steel while retaining its hardness, making it more suitable for high-stress applications.