Introduction

Steel is one of the most versatile and widely used materials in the world. Its strength, durability, and relatively low cost make it an ideal choice for a wide range of applications, from construction and manufacturing to transportation and infrastructure. One of the key factors that determines the properties of steel is its carbon content.Steel carbon content is a fundamental aspect of metallurgy that significantly influences the properties and performance of steel. In this guide, we will delve into the intricate world of steel carbon content, exploring its impact on material characteristics, manufacturing processes, and practical applications.

What is Steel Carbon Content?

Carbon content refers to the percentage of carbon atoms present in a steel alloy. Carbon is a non-metallic element that plays a crucial role in influencing the microstructure and properties of steel. Generally, steel is considered to be carbon steel if it contains less than 2% carbon.

Effect of Carbon Content on Steel Properties

The carbon content in steel has a significant impact on its mechanical properties, such as strength, hardness, ductility, and toughness. As the carbon content increases, the strength and hardness of steel also increase. This is because carbon atoms combine with iron atoms to form hard and brittle cementite (Fe3C) particles, which strengthen the steel matrix.

However, increasing carbon content also comes at the expense of ductility and toughness. Ductility refers to the ability of a material to deform without breaking, while toughness refers to its ability to absorb energy before fracturing. As the carbon content increases, the steel becomes less ductile and tougher, making it more prone to cracking and breaking.

Classification of Steel Based on Carbon Content

Based on their carbon content, steels can be broadly classified into three main categories:

- Low-carbon steel: Low-carbon steel contains less than 0.30% carbon. It is the most ductile and formable type of steel, making it suitable for applications where bending, shaping, or welding is required. Low-carbon steel is often used in construction, pipes, and sheet metal.

| Carbon Content (%) | Range | Properties | Applications |

|---|---|---|---|

| Low-carbon | < 0.30 | Ductile, formable, weldable | Construction, pipes, sheet metal |

| Medium-carbon | 0.30 – 0.60 | Stronger, harder | Shafts, gears, tools |

| High-carbon | 0.60 – 1.50 | Very hard, brittle | Cutting tools, springs |

- Medium-carbon steel: Medium-carbon steel contains between 0.30% and 0.60% carbon. It offers a balance between strength and ductility, making it suitable for applications where both are required. Medium-carbon steel is often used in shafts, gears, and tools.

- High-carbon steel: High-carbon steel contains more than 0.60% carbon. It is the hardest and strongest type of steel, but also the most brittle. High-carbon steel is often used in cutting tools, springs, and other applications where hardness is critical.

Selection of Steel Based on Carbon Content

The choice of steel for a particular application depends on the specific requirements of the application. For instance, if ductility and formability are paramount, low-carbon steel would be the preferred choice. On the other hand, if strength and hardness are the primary concerns, high-carbon steel would be more suitable.

Conclusion: Steel Carbon Content

Carbon content plays a pivotal role in determining the properties of steel. Understanding the relationship between carbon content and steel properties is essential for selecting the right type of steel for a specific application. By carefully considering the requirements of the application, engineers and designers can choose the steel with the optimal carbon content to ensure the desired performance and longevity of the product.

FAQ

Q: What is the difference between carbon steel and stainless steel?

A: Carbon steel and stainless steel are two distinct types of steel with different properties and applications. Carbon steel is primarily composed of iron and carbon, while stainless steel contains additional alloying elements, such as chromium, nickel, and molybdenum, which impart corrosion resistance.

Q: Can the carbon content of steel be changed?

A: Yes, the carbon content of steel can be modified through various heat treatment processes, such as annealing, normalizing, and hardening. These processes involve heating and cooling the steel at controlled rates to alter its microstructure and properties.

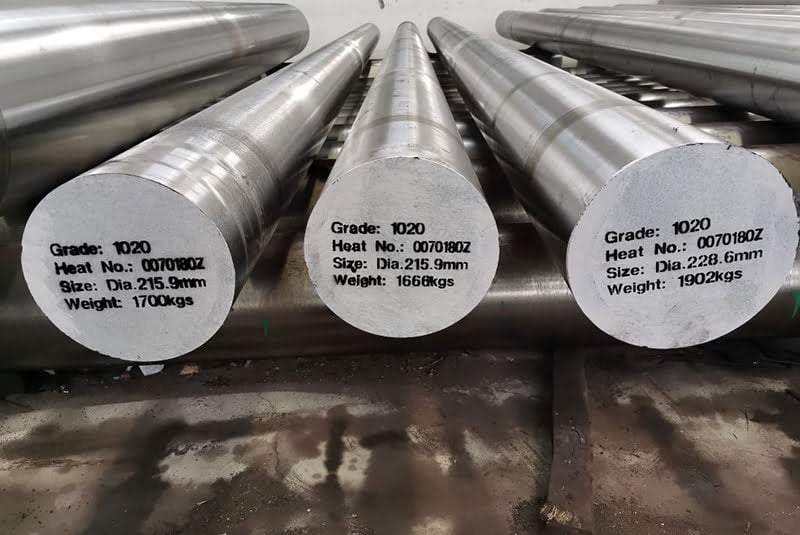

Q: What are some examples of common steel grades?

A: A100, A36, and A529 are common examples of low-carbon steel grades often used in construction and general engineering applications. For medium-carbon steels, 4140 and 4150 are popular grades suitable for shafts, gears, and tools. High-carbon steel grades include O1 and O2, which are used for cutting tools and springs.

Q: Is carbon content the only factor affecting steel properties?

A: No, other alloying elements and manufacturing processes also influence steel properties alongside carbon content.