Introduction

Carbon steel is one of the most widely used materials in the manufacturing and construction industries. Known for its strength, versatility, and affordability, carbon steel is an essential component in a wide range of applications. But what is carbon steel, exactly? This comprehensive overview will delve into the composition, properties, types, and uses of carbon steel, providing you with a thorough understanding of this crucial material.

What is Carbon Steel?

Definition and Composition

Carbon steel is an alloy consisting primarily of iron and carbon. The carbon content typically ranges from 0.05% to 2.1% by weight, depending on the grade. The alloying of iron with carbon significantly enhances its strength and hardness, making it suitable for various applications.

- Iron (Fe): The primary element, providing the base structure.

- Carbon (C): The key alloying element, which increases hardness and strength.

In addition to iron and carbon, carbon steel may contain small amounts of other elements such as manganese, silicon, and copper, which further influence its properties.

Table: Composition of Carbon Steel

| Element | Percentage (%) |

|---|---|

| Iron (Fe) | 97.89 – 99.95 |

| Carbon (C) | 0.05 – 2.10 |

| Manganese (Mn) | 0.30 – 1.65 |

| Silicon (Si) | 0.10 – 0.50 |

| Copper (Cu) | 0.20 max |

Properties of Carbon Steel

Carbon steel is known for several key properties that make it a valuable material:

- Strength and Hardness: The carbon content enhances the material’s strength and hardness.

- Ductility: While higher carbon content increases hardness, it can reduce ductility.

- Malleability: Lower carbon steel is more malleable and easier to shape.

- Conductivity: Carbon steel conducts heat and electricity well.

- Magnetic Properties: It is typically magnetic due to its iron content.

Types of Carbon Steel

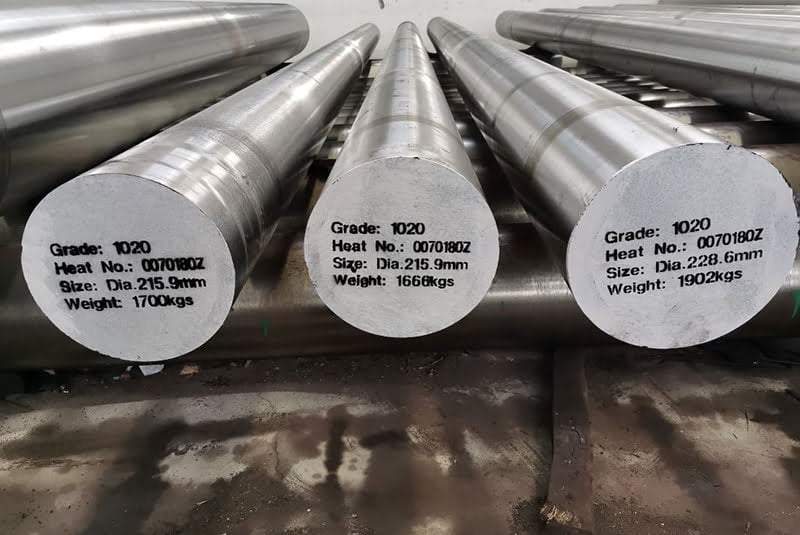

Low Carbon Steel

Low carbon steel, also known as mild steel, contains approximately 0.05% to 0.25% carbon. It is characterized by its ductility and malleability, making it easy to work with.

Applications of Low Carbon Steel

- Automotive Body Panels: Due to its malleability and strength.

- Construction: Used in structural shapes like beams and sheets.

- Pipes: Commonly used for water and gas pipelines.

Medium Carbon Steel

Medium carbon steel contains between 0.26% to 0.60% carbon. It balances ductility and strength, making it suitable for applications that require a good combination of both properties.

Applications of Medium Carbon Steel

- Machinery Parts: Used in gears, axles, and crankshafts.

- Railway Tracks: Provides the necessary strength and durability.

- Forged Products: Suitable for making forged components.

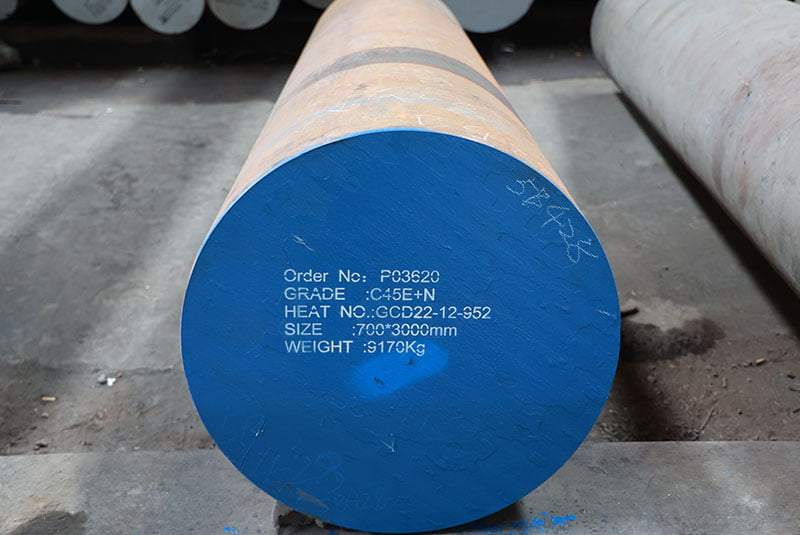

High Carbon Steel

High carbon steel contains between 0.61% to 1.50% carbon. It is very hard and strong but less ductile, making it suitable for applications where high strength and wear resistance are crucial.

Applications of High Carbon Steel

- Cutting Tools: Used in blades, knives, and drill bits.

- Spring Materials: Ideal for manufacturing springs and high-strength wires.

- Industrial Equipment: Utilized in high-wear components.

Ultra-High Carbon Steel

Ultra-high carbon steel contains more than 1.50% carbon. It is extremely hard and brittle, often used in specialized applications.

Applications of Ultra-High Carbon Steel

- Cutting Tools: Specialized tools that require extreme hardness.

- Dies and Molds: Used in the production of dies and molds.

- Military Equipment: Suitable for armor and other military applications.

Heat Treatment and Carbon Steel: What Is Carbon Steel

The Importance of Heat Treatment

Heat treatment processes are used to alter the physical and mechanical properties of carbon steel, enhancing its performance for specific applications. Common heat treatment methods include annealing, quenching, and tempering.

Annealing

Annealing involves heating the steel to a specific temperature and then slowly cooling it. This process softens the steel, making it more workable.

Quenching

Quenching involves heating the steel to a high temperature and then rapidly cooling it in water or oil. This process increases the hardness and strength of the steel.

Tempering

Tempering follows quenching and involves reheating the steel to a lower temperature and then cooling it. This process reduces brittleness while maintaining hardness.

Table: Effects of Heat Treatment on Carbon Steel

| Heat Treatment | Process Description | Effect on Properties |

|---|---|---|

| Annealing | Heat and slow cool | Softens, improves ductility and workability |

| Quenching | Heat and rapid cool | Hardens, increases strength |

| Tempering | Reheat after quenching | Reduces brittleness, maintains hardness |

Applications of Carbon Steel

Construction Industry

Carbon steel is widely used in the construction industry due to its strength and durability. It is used in:

- Structural Beams and Columns: Provides the necessary support for buildings and bridges.

- Reinforcing Bars (Rebar): Used in concrete to improve its tensile strength.

- Pipes and Tubes: Utilized for plumbing, gas lines, and structural applications.

Automotive Industry

In the automotive industry, carbon steel is used to manufacture:

- Body Panels: Provides the strength and formability needed for vehicle exteriors.

- Engine Components: Used in making engine blocks, crankshafts, and gears.

- Chassis: Ensures the structural integrity of the vehicle.

Manufacturing Industry

Carbon steel plays a crucial role in the manufacturing industry, particularly in:

- Machinery Parts: Used to make gears, bearings, and other critical components.

- Tools and Dies: Essential for manufacturing tools and dies due to its hardness.

- Industrial Equipment: Used in heavy machinery and equipment parts.

Other Applications

- Cutting Tools: High carbon steel is ideal for blades, knives, and drill bits.

- Railway Tracks: Medium carbon steel provides the necessary strength and durability.

- Spring Materials: High carbon steel is used for making springs and high-strength wires.

Conclusion: what is carbon steel

Carbon steel is a versatile and essential material used across various industries due to its excellent properties and affordability. By understanding what carbon steel is, its composition, types, heat treatment processes, and applications, you can better appreciate its significance in modern manufacturing and construction.

Whether you are a professional in the field or simply curious about materials science, this comprehensive overview provides valuable insights into the world of carbon steel. Its strength, durability, and versatility make it a preferred choice for numerous applications, from construction and automotive to manufacturing and beyond.

FAQ

What is carbon steel?

Carbon steel is an alloy of iron and carbon, with the carbon content ranging from 0.05% to 2.1%. The carbon content increases the hardness and strength of the steel, making it suitable for various industrial applications.

What is carbon steel used for?

Carbon steel is used in numerous applications due to its strength and durability. Common uses include construction (structural beams and rebar), automotive (body panels and engine components), manufacturing (machinery parts and tools), and more specialized applications like cutting tools and springs.

What is carbon steel made of?

Carbon steel is primarily made of iron and carbon. The carbon content in carbon steel ranges from 0.05% to 2.1%, which determines its classification into low, medium, high, or ultra-high carbon steel. It may also contain small amounts of other elements like manganese, silicon, and copper.

What is carbon steel’s main advantage?

The main advantage of carbon steel is its high strength and hardness, which can be tailored through heat treatment processes. This makes it highly versatile and suitable for a wide range of applications, from construction to tool making.

What is carbon steel’s composition?

Carbon steel’s composition includes iron and carbon as the primary elements, with the carbon content ranging from 0.05% to 2.1%. It may also contain small amounts of manganese, silicon, and copper, which can influence its properties.

What is carbon steel’s hardness compared to other steels?

The hardness of carbon steel varies depending on its carbon content and heat treatment. Generally, carbon steel can be harder than other steels with lower carbon content but less hard than alloy steels specifically designed for extreme hardness and wear resistance.

What is carbon steel’s role in construction?

In construction, carbon steel is used for structural beams, columns, reinforcing bars (rebar), and pipes. Its strength and durability make it an ideal material for supporting structures and reinforcing concrete.

What is carbon steel’s role in the automotive industry?

In the automotive industry, carbon steel is used for making body panels, engine components, and chassis. Its combination of strength and formability makes it suitable for various vehicle parts, ensuring safety and durability.

What is carbon steel’s role in manufacturing?

In manufacturing, carbon steel is used to produce machinery parts, tools, and industrial equipment. Its high strength and durability make it suitable for components that must withstand high stress and wear.

What is carbon steel’s heat treatment process?

The heat treatment process for carbon steel includes annealing, quenching, and tempering. Annealing softens the steel, quenching hardens it, and tempering reduces brittleness while maintaining hardness. These processes enhance the performance and suitability of carbon steel for various applications.