Introduction

In the realm of construction, low carbon steel stands as a cornerstone material, renowned for its versatility, strength, and cost-effectiveness. This ubiquitous alloy, characterized by its low carbon content, has become an indispensable component in a wide range of structures, from towering skyscrapers and intricate bridges to expansive industrial complexes and residential dwellings. This comprehensive guide delves into the intricate world of low carbon steel properties, exploring the characteristics that make it ideal for construction applications.

Key Low Carbon Steel Properties

High Ductility and Malleability

One of the most notable properties of low carbon steel is its high ductility and malleability. This means it can be easily bent, shaped, and formed without breaking or cracking. This property is particularly advantageous in construction, where materials often need to be molded into specific shapes and configurations to fit architectural designs.

Excellent Weldability

Low carbon steel is known for its excellent weldability, which is the ability to be welded without causing defects. This property is critical in construction, where structural components are often joined together through welding. The ability to weld low carbon steel easily and reliably ensures strong and durable joints, contributing to the overall integrity of the structure.

Good Tensile Strength

While not as strong as high carbon or alloy steels, low carbon steel still offers good tensile strength, making it suitable for many structural applications. Its tensile strength allows it to withstand significant forces without failing, providing the necessary support and stability in construction projects.

Cost-Effectiveness

Another significant advantage of low carbon steel is its cost-effectiveness. It is relatively inexpensive to produce and purchase compared to other types of steel. This affordability makes it an attractive option for large-scale construction projects where cost management is crucial.

Corrosion Resistance

While low carbon steel is not as corrosion-resistant as stainless steel, it can be treated or coated to improve its resistance to rust and corrosion. This enhances its durability and longevity in various construction environments, including those exposed to moisture and weathering.

Applications of Low Carbon Steel in Construction

Structural Frameworks

Low carbon steel is widely used in the construction of structural frameworks for buildings and bridges. Its strength and flexibility allow it to support heavy loads and resist various stresses, making it a reliable material for creating sturdy and long-lasting structures.

Reinforcement Bars (Rebars)

Reinforcement bars, or rebars, are essential in concrete construction to provide additional tensile strength. Low carbon steel is commonly used for rebars due to its high tensile strength and cost-effectiveness. These properties help enhance the overall strength and durability of concrete structures.

Building Components

Various building components, such as beams, columns, and trusses, are made from low carbon steel. These components play a critical role in supporting and distributing loads throughout the structure. The weldability and formability of low carbon steel make it ideal for creating these vital construction elements.

Industrial Sheds and Warehouses

Low carbon steel is also used in the construction of industrial sheds and warehouses. Its properties make it suitable for fabricating large, open structures that require both strength and flexibility. Additionally, its cost-effectiveness allows for economical construction of these expansive spaces.

Infrastructure Projects

From bridges and tunnels to railways and pipelines, low carbon steel is a material of choice for various infrastructure projects. Its versatility and performance under different environmental conditions make it suitable for a wide range of civil engineering applications.

Comparison of Low Carbon Steel Properties with Other Materials

| Property | Low Carbon Steel | High Carbon Steel | Stainless Steel | Aluminum |

|---|---|---|---|---|

| Carbon Content | < 0.3% | 0.6% – 1.0% | < 0.1% | None |

| Ductility and Malleability | High | Low | Moderate | High |

| Weldability | Excellent | Poor | Good | Moderate |

| Tensile Strength | Good | High | High | Moderate |

| Corrosion Resistance | Moderate (with treatment) | Low | High | High |

| Cost | Low | Moderate | High | High |

Best Practices for Using Low Carbon Steel in Construction

Proper Treatment and Coating

To enhance the corrosion resistance of low carbon steel, it is essential to apply proper treatments and coatings. Galvanizing, painting, and applying protective sealants can significantly extend the lifespan of low carbon steel structures exposed to harsh environmental conditions.

Quality Control in Welding

Given the excellent weldability of low carbon steel, ensuring high-quality welding practices is crucial. Using appropriate welding techniques and equipment, along with skilled welders, can prevent defects and ensure strong, durable joints.

Regular Maintenance and Inspection

Like any construction material, low carbon steel structures require regular maintenance and inspection. This includes checking for signs of corrosion, wear, and structural integrity. Timely maintenance can prevent minor issues from developing into major problems, ensuring the longevity and safety of the structure.

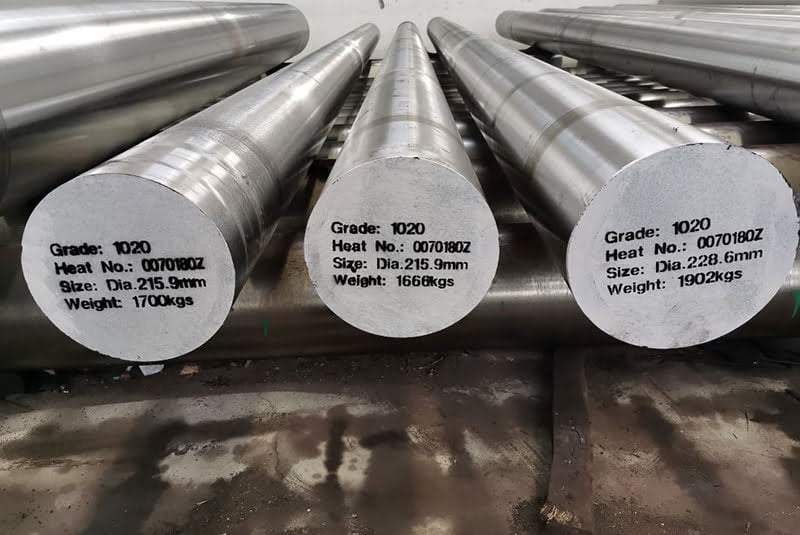

Selecting the Right Grade

Low carbon steel comes in various grades, each with specific properties suited to different applications. Selecting the right grade for your construction project is essential to achieve optimal performance. Consulting with materials engineers or suppliers can help determine the most suitable grade based on the project’s requirements.

Conclusion: Low Carbon Steel Properties

The properties of low carbon steel make it an invaluable material in the construction industry. Its high ductility, excellent weldability, good tensile strength, and cost-effectiveness provide numerous advantages for a wide range of applications. By understanding and leveraging these properties, construction professionals can design and build structures that are both efficient and durable. Proper treatment, quality control, and regular maintenance further enhance the performance and longevity of low carbon steel in construction projects. As the industry continues to evolve, low carbon steel remains a versatile and reliable choice for building the infrastructure of the future.

FAQ

What is Low Carbon Steel?

Low carbon steel is a type of steel that contains a small percentage of carbon, typically less than 0.3%. This composition gives it a range of beneficial properties, including high ductility, good tensile strength, and excellent weldability, making it ideal for various construction applications.

Why is Low Carbon Steel Ideal for Construction?

Low carbon steel is ideal for construction due to its high ductility, excellent weldability, good tensile strength, and cost-effectiveness. These properties make it suitable for structural frameworks, reinforcement bars, building components, and various infrastructure projects.

How Does Low Carbon Steel Compare to High Carbon Steel?

Low carbon steel has lower carbon content, making it more ductile and easier to weld than high carbon steel. While high carbon steel offers greater strength and hardness, low carbon steel is preferred in construction for its flexibility, ease of use, and affordability.

Can Low Carbon Steel Be Used in Corrosive Environments?

Low carbon steel can be used in corrosive environments if it is properly treated or coated to enhance its corrosion resistance. Common treatments include galvanizing, painting, and applying protective sealants to prevent rust and extend the material’s lifespan.

What Are Some Common Applications of Low Carbon Steel in Construction?

Common applications of low carbon steel in construction include structural frameworks for buildings and bridges, reinforcement bars in concrete structures, building components like beams and columns, industrial sheds and warehouses, and various infrastructure projects such as tunnels, railways, and pipelines.