Welcome to My Blog! Before we dive into the content, I’d love for you to join me on my social media platforms where I share more insights, engage with the community, and post updates. Here’s how you can connect with me:

Facebook:https://www.facebook.com/profile.php?id=100085401406977

LinkedIn:https://www.linkedin.com/showcase/102680001/admin/dashboard/

Now, let’s get started on our journey together. I hope you find the content here insightful, engaging, and valuable.

Introduction

Metal service material testing is a critical process that ensures the quality, reliability, and safety of metal products. By subjecting metals to various tests, engineers and manufacturers can gain valuable insights into a material’s properties, performance, and limitations. This knowledge is essential for making informed decisions about material selection, product design, and manufacturing processes. In this blog post, we will delve into the importance of metal service material testing, exploring its various applications, benefits, and the different types of tests conducted.

The Importance of Metal Service Material Testing

Metal service material testing is essential for several reasons:

Quality assurance: By testing materials, manufacturers can ensure that their products meet specified quality standards and customer expectations. This is particularly important in industries where product failures can have serious consequences, such as aerospace, automotive, and medical. For example, a faulty metal component in an aircraft could lead to a catastrophic failure, while a defective medical device could endanger patient safety.

Product development: Testing helps engineers develop new materials and products with improved performance characteristics. By conducting tests on different materials and designs, engineers can identify the most suitable options for a particular application. This can lead to the development of products that are stronger, lighter, more durable, or more corrosion-resistant.

Failure analysis: When a product fails, testing can help identify the root cause of the failure and prevent similar incidents in the future. By analyzing the failed component, engineers can determine whether the failure was due to a material defect, a manufacturing error, or a design flaw. This information can then be used to improve the product’s design and manufacturing process.

Regulatory compliance: Many industries have regulations that require metal products to meet specific performance standards. Testing is necessary to demonstrate compliance with these regulations. For example, the aerospace industry has strict regulations regarding the fatigue strength and fracture toughness of metal components. By testing their products to ensure compliance with these regulations, manufacturers can avoid costly legal penalties and maintain their reputation.

Types of Metal Service Material Testing

There are numerous types of metal service material testing, each designed to evaluate specific properties. Some common tests include:

- Mechanical testing: Measures the strength, ductility, hardness, and toughness of a material. This type of testing is essential for determining a material’s suitability for a particular application. For example, a material used in a structural component must have sufficient strength to withstand the expected loads, while a material used in a flexible component must be ductile to avoid brittle failure.

- Chemical analysis: Determines the chemical composition of a material. This information is important for understanding a material’s properties and behavior. For example, the presence of impurities in a material can significantly affect its strength and corrosion resistance.

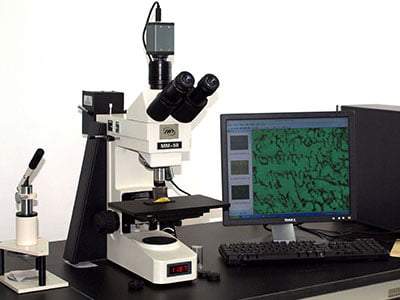

- Metallurgical analysis: Examines the microstructure of a material to identify defects and evaluate its suitability for a particular application. This type of testing can reveal the presence of voids, cracks, or other defects that could compromise a material’s integrity.

- Corrosion testing: Evaluates a material’s resistance to corrosion in various environments. This is particularly important for materials that will be exposed to harsh conditions, such as salt water, acids, or alkalis.

- Non-destructive testing: Detects flaws or defects in a material without damaging it. This type of testing is often used to inspect large or critical components, such as pressure vessels or pipelines. Common non-destructive testing methods include radiography, ultrasonic testing, and magnetic particle testing.

Benefits of Metal Service Material Testing

Metal service material testing offers a wide range of benefits, including:

- Improved product performance: By selecting the right materials and optimizing manufacturing processes, testing can lead to products with superior performance. For example, by testing different materials for a particular application, engineers can choose the one that is most resistant to wear and tear, fatigue, or corrosion.

- Reduced costs: Identifying and addressing potential problems early in the product development cycle can save significant costs. For example, if a material is found to be unsuitable for a particular application during testing, it can be replaced with a more appropriate material before the product is manufactured.

- Increased safety: Testing helps ensure that products are safe for use and will not fail in service. For example, testing can be used to verify that a material has sufficient strength to withstand the loads it will be subjected to in service.

- Enhanced reputation: Demonstrating a commitment to quality through rigorous testing can enhance a company’s reputation. Customers are more likely to trust a company that invests in quality control measures.

Metal Service Material Testing Standards

To ensure consistency and accuracy, metal service material testing is often conducted in accordance with established standards. Some of the most commonly used standards include:

- ASTM International: American Society for Testing and Materials

- ISO: International Organization for Standardization

- EN: European Norm

These standards provide guidelines for various types of metal service material testing, including mechanical testing, chemical analysis, and metallurgical analysis. By following these standards, manufacturers can ensure that their testing procedures are reliable and comparable to those of other companies in the industry.

The Role of Metal Service Material Testing in Different Industries

Metal service material testing plays a critical role in a wide range of industries, including:

- Aerospace: Ensuring the safety and reliability of aircraft components. The aerospace industry has very high standards for the quality of materials used in aircraft construction. Testing is essential to verify that materials meet these standards and can withstand the extreme conditions encountered during flight.

- Automotive: Improving fuel efficiency and reducing emissions. The automotive industry is constantly striving to improve the fuel efficiency and environmental performance of its vehicles. Testing can help identify materials that are lighter, stronger, and more corrosion-resistant, which can contribute to these goals.

- Construction: Selecting materials that can withstand harsh environmental conditions. Materials used in construction must be able to withstand a variety of environmental factors, including temperature extremes, moisture, and corrosive substances. Testing can help ensure that materials are suitable for the specific conditions they will be exposed to.

- Energy: Developing materials for renewable energy applications. The development of renewable energy technologies, such as solar panels and wind turbines, requires the use of materials with specific properties. Testing can help identify and develop materials that are suitable for these applications.

A Closer Look at Mechanical Testing

Mechanical testing is one of the most common types of metal service material testing. It involves subjecting a material to various loads to determine its mechanical properties. Common mechanical tests include:

| Test Type | Purpose |

|---|---|

| Tensile test | Measures a material’s strength, ductility, and modulus of elasticity. This test is used to determine a material’s resistance to tensile forces, which can occur in components such as beams, cables, and wires. |

| Compression test | Determines a material’s resistance to compressive forces. This test is used to evaluate materials that will be subjected to compressive loads, such as columns, foundations, and bearings. |

| Impact test | Evaluates a material’s ability to absorb energy from a sudden impact. This test is used to assess a material’s toughness, which is important for components that may be subjected to shock loads, such as machinery parts and vehicle frames. |

| Hardness test | Measures a material’s resistance to indentation. This test is used to evaluate a material’s wear resistance and its ability to resist scratching or abrasion. |

Conclusion

Metal service material testing is an indispensable part of the product development and manufacturing process. By providing valuable insights into a material’s properties and performance, testing helps ensure the quality, reliability, and safety of metal products. As technology continues to advance, the importance of metal service material testing is only expected to grow.

FAQ

What is the difference between destructive and non-destructive testing?

Destructive testing involves destroying the sample being tested, while non-destructive testing does not. Destructive testing is often used to determine the ultimate strength of a material, while non-destructive testing is used to detect defects or flaws in a component without damaging it.

How often should metal service material testing be performed?

The frequency of metal service material testing depends on the specific application and the level of risk involved. Critical components, such as those used in aerospace or medical applications, may require more frequent testing than less critical components.

What factors can affect the results of a metal service material test?

Several factors can affect the results of a metal service material test, including the test method used, the sample preparation, and the environmental conditions. It is important to follow established standards and procedures to ensure accurate and reliable results.

How can I choose the right testing laboratory for my needs?

When selecting a testing laboratory, it is important to consider factors such as the laboratory’s experience, accreditation, and equipment capabilities. It is also important to ensure that the laboratory can provide the specific types of testing that you need.